GH625 alloy is a nickel-base alloy having excellent stress-rupture properties and good oxidation resistance to 1200F. It is recommended for jet engine components, aerospace applications and chemical processing equipment. As a benchmark material among modern wrought superalloys, it remains consistently accessible through global super alloy suppliers specializing in high-temperature solutions.

Similar alloy's names in different standards:

Beiye designation | American designation | French designation | German designation |

GH625 | UNS N06625 | NC22DNb | Nr.2.4856 |

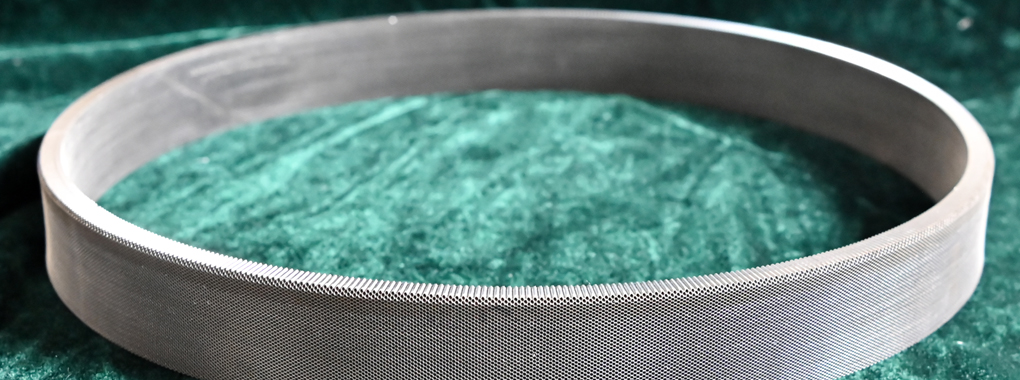

Jet engine components

Aerospace equipment

Chemical processing construction

Sea-water equipment

C | 0.10 | Mn | 1.00 |

| Si | 0.50 | Fe | 1.50 |

Cu | 31.50 | Ni | bal. |

| Solution | Cold Rolled | |

Yield Strength | 510 MPa (74 ksi) | 724 MPa (105.1 ksi) |

Tensile Strength | 950 MPa (137.9 ksi) | 1102 MPa(160ksi) |

| Elongation | 44.5% | 30% |

* Typical values for material tested in accordance with GB/T 4340.3, GB/T 228, GB/T 22315.

Density | 8.44g/cm3 (0.305lb/in3) | ||

Melting Point | 1350 ℃ (2462oF) | ||

Modulus of elasticity (20℃,Tension) | 205.3GPa(29.8×103ksi) | ||

(20℃,Torsion) | 78.5GPa(11.4×103ksi) | ||

Poisson's rato (21℃) | 0.308 | ||

Annealing: Mill annealing is accomplished by heating at 930~1040℃ for up to one hour.

Solution Annealing: Heat to 1100~1200℃ and cool in air or quench.

Stress Relieving: Heat at 900℃ for times commensurate with thickness and cool.

If you want to know more about our nickel-based superalloys and their technical specifications, please do not hesitate to contact Beiye, your reliable partner for precision alloy and supply.