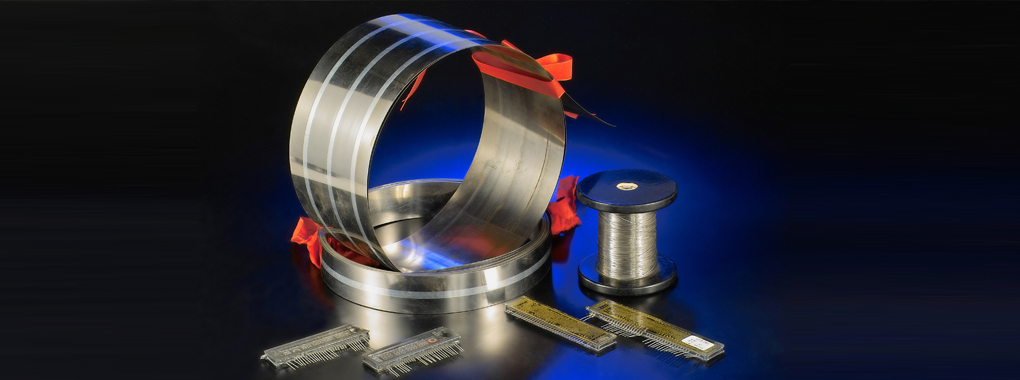

PH15-7Mo

PH15-7Mo is a kind of austenite precipitation hardening special stainless steel. The material in solid solution condition has good ductility, which can be deformed easily. The material in the precipitation hardened condition, is strengthened by precipitating second precipitation phase, so the material in precipitation hardened condition has high strength, high hardness, and has tolerable ductility. The material is mainly used to made container, parts and structural parts, which require high corrosion resistance and high strength properties.

C286

C286 is a kind of high-strength, no hairline, non-magnetic austenitic special stainless steel. The material in solid solution condition has good ductility, which can be deformed easily. The material in aged condition, precipitates second precipitation phase, so the material in aged condition has high strength, high hardness, and the material has low magnetic, and certain resistance to salt and acid corrosion properties. C286 is mainly used for making vacuum devices, parts and structural parts, such as the motor shaft and the sleeve.

Domestic and foreign designations:

Beiye | China Standard | America | Russia |

PH15-7Mo | 07Cr15Ni7Mo2Al (0Cr15Ni7Mo2Al) | AISI632/UNS15700 | Z10CNDA15.07 |

The chemical composition of PH15-7Mo is as follow:

C | ≤0.09% | Si | ≤1.00% | Mn | ≤1.00% |

Cr | 14.00~16.00% | Ni | 6.50~7.75% | Mo | 2.00~3.00% |

Al | 0.75~1.50% | Fe | bal. | ||

P | ≤0.040% | S | ≤0.030% |

The nominal chemical composition of PH15-7Mo is as follow:

C | ≤0.08% | Si | ≤0.80% | Mn | ≤0.80% |

P | ≤0.02% | S | ≤0.02% | V | ≤0.5% |

Cr | 17% | Ni | 26% | Ti | 3% |

Al | 0.5% | Fe | bal. |

Typical mechanical properties of PH15-7Mo:

solid solution condition | precipitation hardened condition | |

Tensile Strength, Rm | 850 MPa (123.25 ksi) | 1600MPa(232 ksi) |

Yield strength, Rp0.2 | 420 MPa (60.9 ksi) | 1450MPa(210.25 ksi) |

Elongation, A | 40% | 15% |

Hardness, HV | 225 | 480 |

Typical mechanical properties of C286 in aged condition:

Tensile Strength, Rm | 1200 MPa ( ksi) |

Yield strength, Rp0.2 | 900 MPa ( ksi) |

Elongation, A | 20% |

Reduction of area, Z | 35% |

Hardness, HV | 350 |

Magnetic property of C286 in forging state:

Magnetic permeability | μ100≤1.006 Gs/Oe |

Remanence | Br1000≤0.15Gs |

PH15-7Mo | C286 | |

Density | 7.7g/cm3 | 7.8g/cm3 |

Melting Point | 1480℃ (2696℉) | 1380℃ (2516℉) |

For detailed quotes on PH15-7Mo and C286 special stainless steel, consult Beiye — your trusted partner for high-performance precision alloy and supply.