BYR8 is a Iron-Nickel-Molybdenum alloy with the Nickel and Molybdenum content are about 80% and 4.3% respectively, and possesses high permeability combined with low coercivity and core losses, which makes this soft iron alloy been used widely in laminated cores for instrument transformers, sensors, magnetic amplifiers and shielding, and mainly supplied as sheets.

| C | Si | Mn | Ni | Mo | Fe |

| 0.03 | 0.30 | 0.45 | 80 | 4.3 | Bal. |

| Density (g/cm3) | Melting T (℃) | Curie T (℃) | Thermal expansion (10-6/K) | Resistivity (µΩ·cm) | Thermal conduction (W/m·K) |

| 8.75 | 1460 | 420 | 13 | 60 | 19 |

| State | Hardness(HV) | Rp0.2 (MPa) | Rm (MPa) | A (%) | |

| Sheet | Cold-rolled | 340 | 1050 | 1100 | 5.0 |

| Fully-annealed | 105 | 140 | 450 | 35 | |

| Mill-annealed | 160 | 300 | 650 | 40 |

* The test shall be conducted in accordance with GB/T 4340.3, GB/T 228, and GB/T 22315 standards.

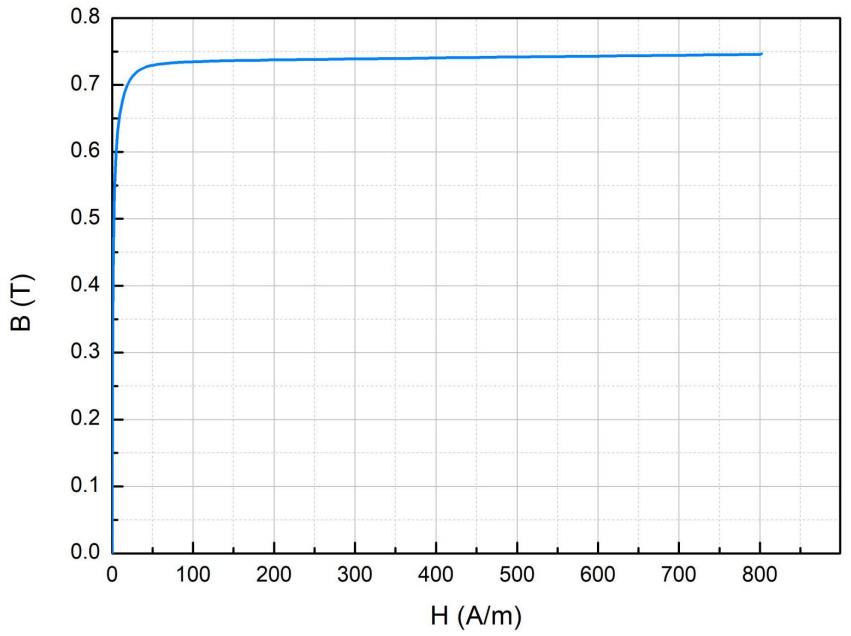

| Dimension (mm) | μ0 (mH/m) | μm (mH/m) | Hc (A/m) | Bs (T) | |

| Sheet | 0.35 | 100 | 225 | 0.8 | 0.75 |

* The ring sample was tested after heat treatment at 1180°C×5h in pure hydrogen atmosphere; μ0 was measured at H = 0.08A/m; Bs was measured at H = 800A/m.

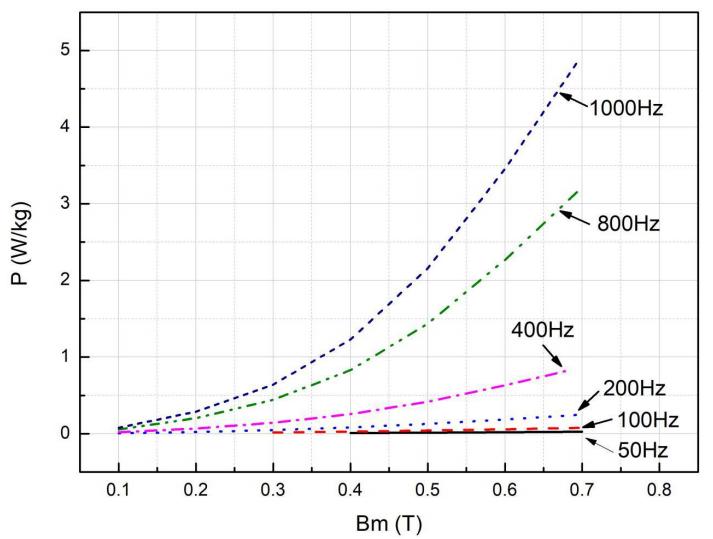

0.15mm Strip loss curve

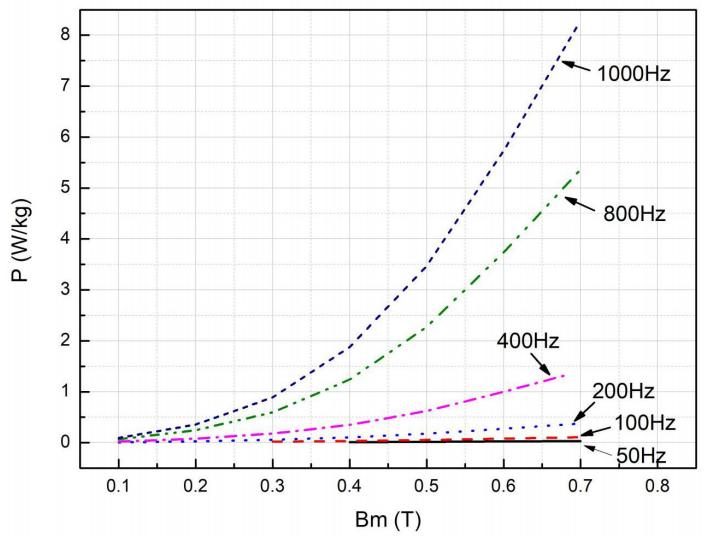

0.2mm Strip loss curve

Feel free to contact Beiye for further details on BYR8 and our precision alloy and supply services.