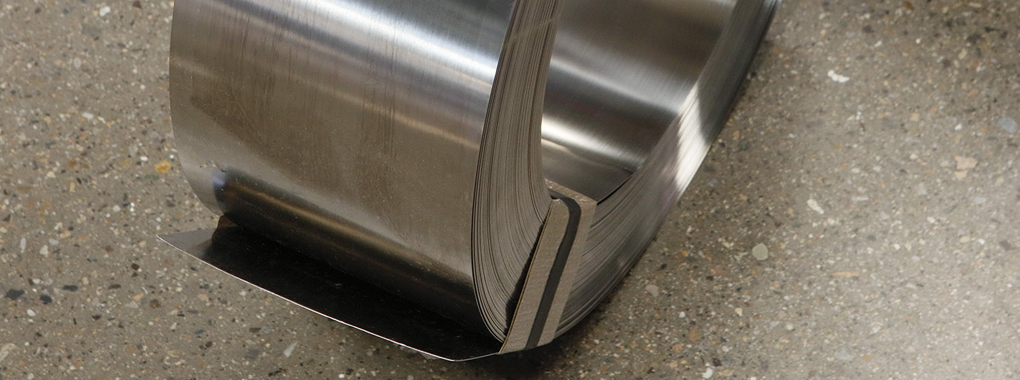

17-4PH is a special stainless steel of the martensitic precipitation-hardening type, also designated as 0Cr17Ni4Cu4Nb. The strength level of this alloy can be precisely adjusted through heat treatment processes. Its primary strengthening mechanisms are martensitic transformation and the formation of hardening precipitates during aging. A properly processed 17-4PH alloy exhibits excellent overall performance, including outstanding resistance to corrosion, fatigue, and erosion from water droplets. This technical overview is based on the expertise and material specifications provided by Beiye, a specialist in precision alloy and supply.

Domestic and foreign designation:

Beiye | China Standard | America | Germany | Japan |

74 | 0Cr17Ni4Cu4Nb | AISI630 | SUS630 |

C | ≤0.07% | Cu | 3~5% |

Si | ≤1.00% | Cr | 15.5~17.5% |

Mn | ≤1.00% | Ni | 3~5% |

| P | ≤0.035% | Nb | 0.15~0.45% |

S | ≤0.030% | Fe | Bal |

Aging at 480℃ | Aging at 550℃ | Aging at 580℃ | Aging at 620℃ | |

Tensile strength, σb (MPa) | ≥1310 | ≥1060 | ≥1000 | ≥930 |

Yield strength, σ0.2 (MPa) | ≥1180 | ≥1000 | ≥865 | ≥725 |

Elongation, δ5 (%) | ≥10 | ≥12 | ≥13 | ≥16 |

Reduction of area, ψ (%) | ≥40 | ≥45 | ≥45 | ≥50 |

Hardness | ≥375HB(≥40HRC) | ≥331HB(≥35HRC) | ≥302HB(≥31HRC) | ≥277HB(≥28HRC) |

Solution heat treatment at 1020~1060℃, rapid cooling; then aging treatment, air cooling.

Density, g/cm3 | 7.78 |

Elastic Modulus, E, 103MPa (103ksi) | 213 (30.885) |

Thermal conduction λ, W∕ (m·K) | 15.9 |