GH536 is a nickel-chromium-iron-molybdenum alloy that possesses an exceptional combination of oxidation resistance, fabricability and high-temperature strength. This high-temperature alloy has been found to be exceptionally resistant to stress-corrosion cracking in petrochemical applications.Below 900℃, it has moderate stress rupture and creep strength, cold and hot working formability and good weldability. GH536 alloy is widely used in gas-turbine engines, industrial furnace applications, and chemical process industries. Similar wrought alloy's names in different standards:

Beiye | China | America | France | Germany | Britain |

GH536 | GH3536 | HastelloyX | NC22FeD | NiCr22FeMo | Nimonic PE13 |

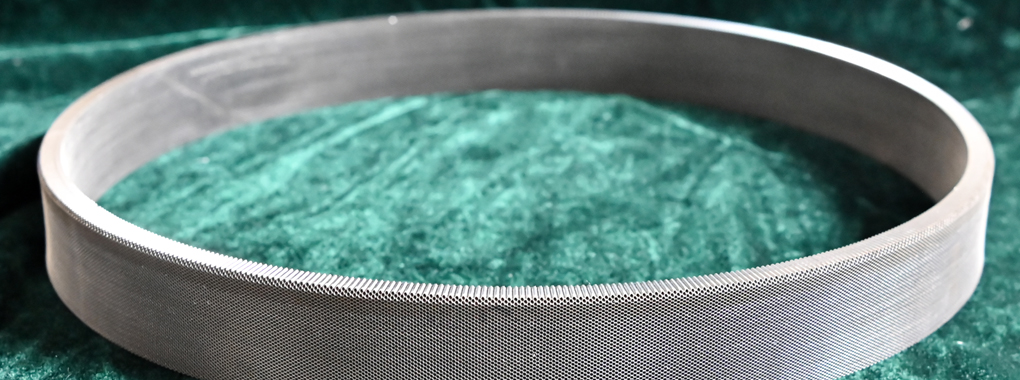

Honeycomb seal structure

Fuel conduit

Combustor components

C | 0.07 | Ni | Bal. |

Cr | 21.50 | Mo | 9.00 |

Co | 2.13 | Fe | 18.90 |

W | 0.60 | B | 0.005 |

Soft | |

Yield Strength | 447 MPa |

Tensile strength | 834 MPa |

| Elongation | 47% |

* 0.6mm thick strip sample

Density | 8.28 g/cm3 | ||

Melting Point | 1295~1381℃ | ||

Thermal conductivity | 31.14 W/(m·℃) (800℃) | ||

Thermal expansion | 16.1×106℃(20~900℃) | ||

In-process annealing: To relieve all strains and restore the alloy to a soft condition suitable for further cold rolling or drawing, forming, bending or similar operations, anneal at 1065~1150℃ for not more than 1 hour. Since the high nickel, high permeability alloys readily absorb carbon, sulfur, oxygen and other contaminants from combustion furnace gasses, in-process annealing should be conducted in hydrogen, vacuum or inert gas atmospheres.

Final annealing: For maximum softness and optimum magnetic electrical properties, the cold deformed GH536 alloy should be solution treated in an oxygen-free, dry hydrogen atmosphere at 1065~1150℃ with air cooling, and the heat treatment time is determined based on the strip thickness.

In order to ensure the quality of the strip surface, oil, grease, lacquer and all other contaminants must be removed before annealing.

For professional guidance on heat treatment processes and reliable material sourcing, please contact Beiye, your trusted partner in precision alloy and supply.