GH4169 is the most widely used Nickel-based superalloy for turbine disc in gas turbine and jet engines with service temperatures up to 923 K because of its high temperature strength and corrosion resistance. This material represents one of the most successful wrought alloys examples in aerospace history and continues to be a core product offered by leading super alloy suppliers worldwide. Similar alloy's names in different standards:

Beiye designation | China Standard designation | America designation | France designation |

GH4169 | GH4169 | Inconel 718 (UNS N07718) | NC19FeNb |

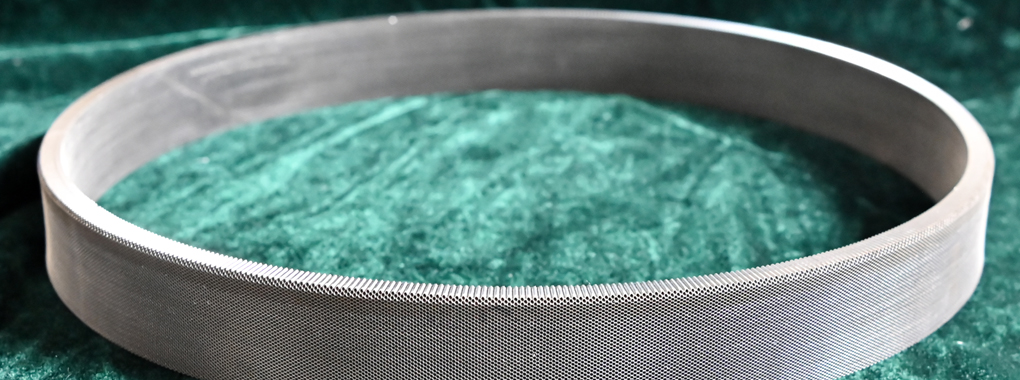

Turbine disk

Rocket motor

Nuclear reactor

C | 0.04 | Cr | 18.56 |

Ti | 1.02 | Al | 0.57 |

Mo | 3.06 | Ni | 52.89 |

Nb | 5.10 | Fe | bal. |

Hardness | Hot-working | HRC20 |

GR | HRC18 | |

Aging Treatment | HRC42 | |

Breaking Strength At 25℃ | Cold-working | 1250Mpa |

Yield Strength At 25℃ | Cold-working | 1100Mpa |

Elongation At 25℃ | Cold-working | 15% |

Breaking Strength At 25℃ | Aging Treatment | 1300/18000Mpa |

Yield Strength At 25℃ | Aging Treatment | 1150/1700Mpa |

Elongation At 25℃ | Aging Treatment | 6% 24% |

Breaking Strength At 650℃ | Aging Treatment | 1100Mpa |

Yield Strength At 650℃ | Aging Treatment | 900Mpa |

Elongation At 650℃ | Aging Treatment | 18% |

The melting temperature | 1260~1320℃ | ||

Density | 8.3g/cm3 | ||

Linear expansivity | 400℃ | 500℃ | 600℃ |

14.5 | 14.9 | 15.2 | |

With the advanced metallurgy of Beiye and the material expertise of precision alloy and supply, GH4169 wrought superalloy delivers unmatched reliability for your most critical missions.