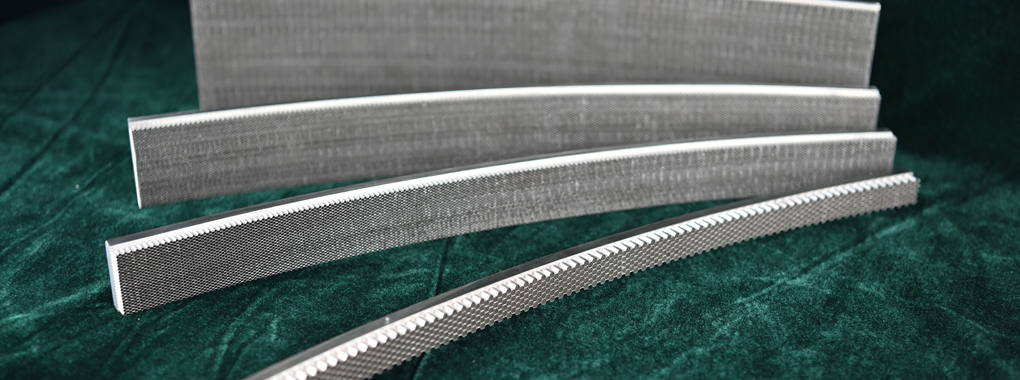

GH3030 is a solid solution strengthening 80Ni-20Cr alloy. Its chemical composition is simple. Below 800 ℃, it has a satisfactory heat resistance, high ductility, and good resistance to oxidation, thermal fatigue, cold stamping and welding performance. After solution treatment, GH3030 alloy become austenite single-phase, and has good structure stability during use. The main products are cold-rolled sheet, bars, rings, wire and so on. This versatile wrought alloy is available through established precision alloy and supply networks worldwide. Similar alloy's names in different standards:

Beiye | China | Russia |

GH3030 | GH3030 | ЭИ435 |

Turbine engine combustor components

High temperature container

Thermocouple protection cover

C | 0.022 | Ni | Bal. |

Cr | 20.80 | Ti | 0.30 |

Soft | |

| Tensile Strength | 713 MPa |

| Elongation | 44.5% |

* 0.4mm thick strip sample

Density | 8.40 g/cm3 | ||

Melting Point | 1374~1420℃ | ||

Thermal conductivity | 25.1 W/(m·℃) (800℃) | ||

Thermal expansion | 18.0×106℃(20~900℃) | ||

In-process annealing: To relieve all strains and restore the alloy to a soft condition suitable for further cold rolling or drawing, forming, bending or similar operations, anneal at 1120~1200℃ for not more than 1 hour. Since the high nickel, high permeability alloys readily absorb carbon, sulfur, oxygen and other contaminants from combustion furnace gasses, in-process annealing should be conducted in hydrogen, vacuum or inert gas atmospheres.

Final annealing: For maximum softness and optimum magnetic electrical properties, the cold deformed GH3030 alloy should be solution treated in an oxygen-free, dry hydrogen atmosphere at 1120~1200℃ with air cooling, and the heat treatment time is determined based on the strip thickness.

In order to ensure the quality of the strip surface, oil, grease, lacquer and all other contaminants must be removed before annealing.

As a specialized precision alloy manufacturing company, Beiye has been committed to developing and supplying high-performance super alloys that meet stringent industry standards. With extensive expertise in heat treatment processes and material properties, we have established ourselves as a leading super alloy suppliers dedicated to providing reliable technical support and premium alloy solutions. Our consistent quality control and customer-focused approach make us your trusted partner in the precision alloys industry.