HGH625 alloy is a kind of welding material that based on GH625 nickel-based superalloy with strict components requirements. It has excellent plasticity, toughness and crack resistance. Weld metal has high strength and good corrosion resistance at room temperature and high temperature. This combination of properties makes it an outstanding wrought alloy, ideally suited for critical joining applications in aerospace and energy sectors, meeting the stringent standards expected from leading super alloy manufacturers.

Similar alloy's names in different standards:

Beiye designation | American designation |

GH625 | N06082 |

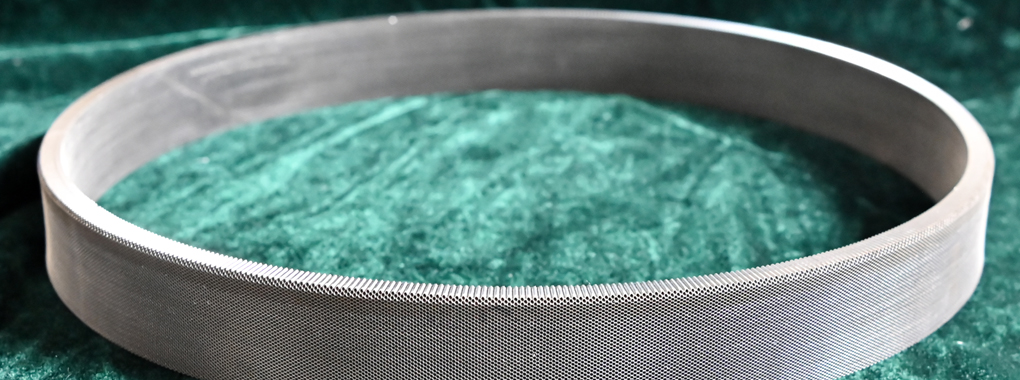

Turbine disk

Rocket motor

Nuclear reactor

C | 0.04 | Cr | 18.56 |

Ti | 1.02 | Al | 0.57 |

Mo | 3.06 | Ni | 52.89 |

Nb | 5.10 | Fe | bal. |

Hardness | Hot-working | HRC20 |

GR | HRC18 | |

Aging Treatment | HRC42 | |

Breaking Strength At 25℃ | Cold-working | 1250Mpa |

Yield Strength At 25℃ | Cold-working | 1100Mpa |

Elongation At 25℃ | Cold-working | 15% |

Breaking Strength At 25℃ | Aging Treatment | 1300/18000Mpa |

Yield Strength At 25℃ | Aging Treatment | 1150/1700Mpa |

Elongation At 25℃ | Aging Treatment | 6% 24% |

Breaking Strength At 650℃ | Aging Treatment | 1100Mpa |

Yield Strength At 650℃ | Aging Treatment | 900Mpa |

Elongation At 650℃ | Aging Treatment | 18% |

The melting temperature | 1260~1320℃ | ||

Density | 8.3g/cm3 | ||

Linear expansivity | 400℃ | 500℃ | 600℃ |

14.5 | 14.9 | 15.2 | |

With the advanced metallurgy of Beiye and the material expertise of precision alloy and supply, GH4169 wrought superalloy delivers unmatched reliability for your most critical missions.