Inco713C is a kind of Nickel-based casting alloy which has lighter weight and good anti-oxidation, anti-fatigue properties in the following 980 ℃, good fatigue and creep rupture strength. The reliable performance of such a complex material is ensured when sourced from a dedicated cast alloy factory with expertise in precision alloy and supply. Similar alloy's names in different standards:

Beiye designation | China Standard designation | America designation | Britain designation |

Inco713C | Inco713C | Nimocast713 |

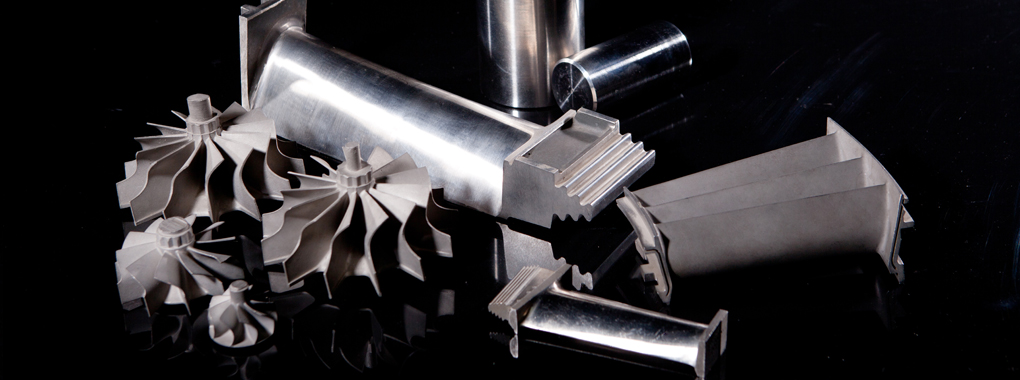

Guide vanes

The working blades

Turbo

C | 0.17 | Cr | 12.80 |

Ti | 0.80 | Al | 6.10 |

Mo | 4.06 | Fe | 0.30 |

Nb | 2.20 | Ni | bal. |

Casting | |

Hardness | 33~37HRC |

Room Temperature Tensile | |

Yield Strength | 730 MPa (105.85 ksi) |

Tensile Strength | 930 MPa (134.85ksi) |

| Elongation | 7.7% |

High Temperature Tensile At 650℃ | |

Yield Strength | 735 MPa (106.58 ksi) |

Tensile Strength | 921 MPa (133.55ksi) |

| Elongation | 8.2% |

High Temperature Tensile At 760℃ | |

Yield Strength | 760 MPa (110.20 ksi) |

Tensile Strength | 918 MPa (133.11ksi) |

Elongation | 8.4% |

High Temperature Rupture At 982℃ | |

Rupture Life | >30h |

Elongation | 12.0% |

* Typical values for material tested in accordance with GB/T 4340.3, GB/T 228, GB/T 22315.

The melting temperature | 1295~1345℃ | ||

Density | 7.9g/cm3 | ||

Thermal expansion | 100℃ | 200℃ | 300℃(W/(m•C)) |

10.15 | 11.72 | 12.98 | |

Specific heat capacity | 100℃ | 198℃ | 315℃(J/(Kg•K)) |

439 | 460 | 481 | |

As one of the leading super alloy manufacturers, Beiye guarantees the material integrity and consistency required for these critical high-temperature applications.